Contacts

-

Institute of Materials and Structures

Ķīpsalas street 6A, Riga,

LV-1048, Latvia -

Project Manager / Leading Researcher

Kaspars KalniņšPhone: +371 67089164

Mob.: +371 26751614

kaspars.kalnins@rtu.lv

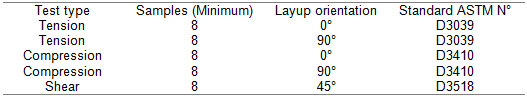

The material characterization is performed using, according to ASTM Standards. Tension, compression and shear samples are fabricated and placed between two aluminum plates for curing, giving a more uniform thickness distribution along their length. The entire setup is closed with a vacuum bag and heated using an oven up to 160 °C for 8 hours.

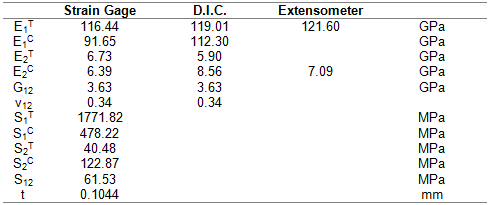

A summary of the calculated material properties are presented in Table 1, where the Eij is the elastic modulus along the fiber direction (i = 1) or matrix direction (i = 2) in tension (j = T) or compression (j = C). G12 is the shear modulus and v12 is the Poisson ratio. Sij is the maximum strength along the fiber direction (i = 1) or matrix direction (i = 2) in tension (j = T) or compression (j = C). S12 is the shear strength. t is the ply thickness.

The material properties are calculated using three different methodologies according to the system used to perform the deformation measurements: Strain gages, digital image correlation (DIC) or mechanical extensometer. The experimental setup for each case is presented in the following sections.

All the tests parameters needed to characterize the mechanical properties of the material are based on the ASTM standards. The type o test, samples and general information are presented on Table 2.

Institute of Materials and Structures

Ķīpsalas street 6A, Riga,

LV-1048, Latvia

Project Manager / Leading Researcher

Kaspars Kalniņš

Phone: +371 67089164

Mob.: +371 26751614

kaspars.kalnins@rtu.lv